Laser marking in furniture construction

Mark fittings, logos and serial numbers precisely and permanently

Precision, efficiency and durability are among the decisive factors in modern furniture construction. In addition to design and functionality, the marking of individual components is also playing an increasingly important role - whether for reasons of traceability, brand communication or quality assurance.

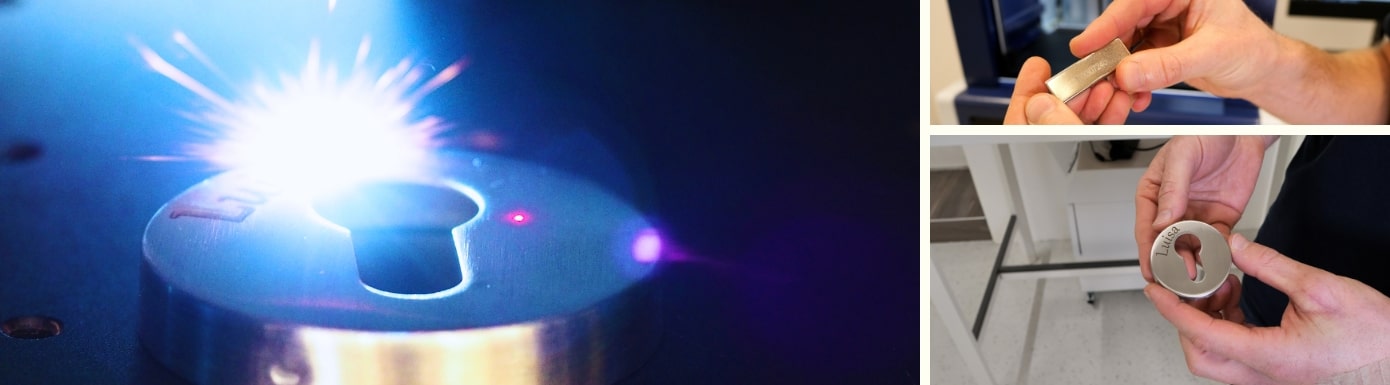

Laser marking of furniture fittings has established itself as a particularly reliable and economical solution. Not only can serial numbers, logos and technical information be permanently applied, but intricate details can also be realized with high repeat accuracy.

The advantages of laser marking

Laser marking is a non-contact method that ensures precision and durability when marking materials. This technology is particularly suitable for marking furniture fittings, as it offers high resistance to abrasion and external influences. It also enables quick and flexible adaptation to different materials and designs.

Precision and attention to detail

Laser marking can be used to create the finest details and complex graphics on various materials. This precision is particularly important for the furniture industry, where design and aesthetics play a crucial role. Whether it's intricate patterns or detailed logos, laser marking offers razor-sharp results.

Durability and resistance

Laser marking is extremely durable and resistant. It does not fade and is insensitive to external influences such as UV radiation, chemicals and mechanical stress.

Why mark furniture fittings with a laser?

Furniture fittings - such as hinges, connectors, handles or drawer pull-outs - are essential components in furniture construction. They often have to withstand high mechanical loads and should also be aesthetically integrated into the design. Laser marking of furniture fittings offers additional advantages:

- Durability: laser engravings are smudge- and scratch-resistant, UV-resistant and legible over the entire service life of the component - ideal for serial numbers or production data.

- Tamper-proof: Manufacturer logos or QR codes for traceability are tamper-proof and cannot be easily removed or altered.

- Flexibility: Even small batches or individual engravings are possible without retooling or long lead times - perfect for custom-made products or individual customer requests.

- Environmentally friendly: Marking is contactless and without the use of inks, solvents or chemical additives.

Application examples in furniture construction

The possibilities offered by laser marking in furniture construction are many and varied. Some of the most common applications are explained below.

Marking furniture fittings

Furniture fittings such as hinges, handles and drawer runners can be individually marked using laser marking. These markings can contain information such as manufacturer logos, serial numbers or technical specifications. Thanks to the high precision and flexibility of laser technology, even the smallest components can be marked reliably and permanently.

Engraving metal

The majority of furniture fittings are made of metals such as stainless steel, aluminium, brass or galvanized steel. These materials can be excellently processed with an industrial marking laser. Depending on the material, different processes such as deep engraving, annealing marking or layer ablation are used.

Laser engraving on metal impresses with particularly fine details, high contrasts and extreme durability. Even the smallest serial numbers or microcodes can be applied legibly and permanently - even on complex geometries or hard-to-reach areas.

Furniture construction in the digital age: traceability and smart factory

In an increasingly digitalized industry, the traceability of components is becoming more and more important. Serial numbers, production data or QR codes, which are applied to furniture fittings by laser, form the basis for digital production processes and smart factory concepts. Production data can thus be automatically recorded, assigned and evaluated - a clear competitive advantage in the age of Industry 4.0.

Laser marking also plays a key role in quality assurance. Faulty batches can be identified quickly, recalls can be handled efficiently and production processes can be optimized. Seamless labeling thus becomes the key to greater transparency and efficiency.

Making brands visible: Engraving logos on furniture components

In addition to functional information, brand logos, design elements or decorative engravings can also be permanently applied to furniture fittings. Branding plays a decisive role, especially for premium manufacturers in the furniture sector. Laser engraving enables high-quality, precise and unobtrusive branding that integrates harmoniously into the overall design.

Whether a filigree logo on a stainless steel handle or stylized lettering on an aluminium connector - the material remains intact thanks to the contactless processing, while the engraved motif leaves a noble and long-lasting impression.

Technological requirements and possibilities

Certain technological requirements are necessary in order to make optimum use of the advantages of laser marking in furniture construction. High-quality laser systems that enable precise control and adjustment of the laser parameters are essential.

Suitable laser systems

There are various laser systems that can be used for marking furniture and fittings. CO2 lasers, for example, are ideal for processing wood and plastic, while fiber lasers are ideal for engraving metals. Choosing the right laser system depends on the specific requirements and materials to be processed.

Software and control

Modern laser systems are equipped with powerful software that makes it easy to design and control the marking processes. This software offers numerous design options and ensures precise implementation of the designs. It can also be integrated into existing production and quality assurance systems.

Conclusion: Laser marking as a key technology in furniture construction

The requirements in modern furniture construction are constantly growing - both technically and in terms of design. Laser marking of furniture fittings offers a high-precision, economical and sustainable solution for the permanent marking of components. Whether serial number, logo or technical symbol - industrial laser systems can reliably meet all quality, traceability and design requirements.

If you want to engrave metal to mark or finish furniture components, an industrial laser marker is a future-proof and versatile technology. Particularly in series production, but also for customer-specific small series, laser marking impresses with maximum flexibility, process reliability and quality at the highest level.