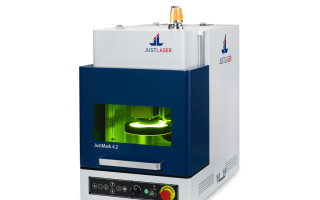

The modern JustLaser laser machines don’t just combine a low investment risk with high productivity, they also win people over with a whole range of benefits:

Modern JustLaser laser machines can mark even complex designs with fine, thin lines accurately and with maximum precision.

Marking products with serial numbers or barcodes through laser engraving is significantly faster than mechanical processes. The simple setup and high throughput speeds of JustLaser laser machines enable cost-effective production – for individual parts or entire product ranges. Hundreds of items can be processed simultaneously thanks to practical mounting devices.

The laser marking process is direct and contactless. No costs are incurred for consumable materials or tool wear as individual components are not fixed in place, do not require pre-treatment or post-treatment, and do not need to be treated with a tool.

Marking products with serial numbers or barcodes using laser machines produces permanent, abrasion-resistant, high-contrast, heat-resistant and acid-resistant results.

Create the design in your graphics software and send the print job to your JustLaser laser machine. You can make further adjustments using the JustLaser Cockpit laser software.