Aramids – shorthand for aromatic polyamides – are liquid crystal polymers (LCP), which are mostly manufactured as fibres in the form of film, paper or particulates. They are characterised by their golden yellow colour. Aramids are high-tensile fibres that are resistant to high temperatures, and can even withstand temperatures in excess of 370 °C. The material is divided into meta-aramids, para-aramids and para-aramid copolymers. Kevlar is part of the group of para-aramids and was developed by Dupont in 1965. It is known for its high strength and relatively low weight.

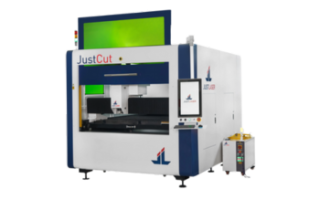

The efficient laser machines have definitely proven themselves as the right choice for cutting aramids and Kevlar as they can cut and sever the special material extremely precisely.

THE AREAS OF APPLICATION FOR ARAMID AND KEVLAR

Aramid and Kevlar are very strong and resistant to acids, alkaline solutions and heat. The material is also distinguished by its low weight. Aramid is often used in the security sector and is principally used for reinforcing textiles – either as protection around the body or to increase the lifespan of items of clothing. Typical applications of aramid are:

- Bulletproof vests

- Cut-resistant clothing

- Splinter protection

- Protective helmets

- Protection against fire, e.g. for protective suits for the fire brigade

- Lines for paragliders

- Sails for sailing boats

- Bike tyres

- Kevlar reinforcements for bike clothing, motorbike clothing and motorsports clothing

- Technical components in vehicle construction, e.g. for armour plating

- Aircraft construction, e.g. for the engine cowling of jet engines

- Seals

- Electrical insulation, etc.