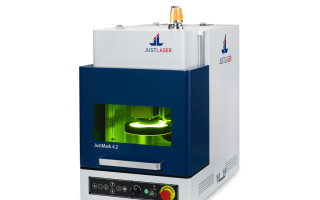

Laser marking with a JustLaser Laser Marker is a precise, high-contrast and gentle form of metal marking. It is contactless, and results in forgery-proof, permanent markings. Anyone who wants to have their turning tools and milling tools marked with a laser can enjoy significant benefits in comparison to other methods such as embossing or etching:

Not only can the method be used on a wide variety of material surfaces and tools, it can also be adapted for a variety of shapes and patterns.

Even small, fine and complex markings and difficult-to-reach places can be marked using the modern laser marker from JustLaser.

Laser markings are permanent, high-contrast and forgery-proof, and are even resistant to high thermal stress, abrasion and acid.

As lasers process materials without making contact, the process is gentle on all materials. It is not necessary to carry out pre-treatment or post-treatment on the workpiece.

As workpieces are not fixed or treated with tools, no additional costs are incurred due to consumable materials or tool wear.

As laser marking saves on operational steps in comparison to mechanical processes, doesn’t require set-up time and can be easily automated, you can benefit from significantly increased production efficiency. The high throughput speed of JustLaser Laser Markers facilitates low-cost production for both individual production and mass production.