Stamp text plates are manufactured from rubber. This is basically a natural product. In technology, however, elastomers made through the vulcanisation of natural and synthetic caoutchouc are also known as rubber. Rubber is particularly flexible and elastic despite its strength and stability of form and contributes to the durability, safety and user-friendliness of a wide variety of products – for example with car tyres, signage, in the fashion industry (shoe soles, rubber boots, protective clothing) and office supplies, etc. However, manufacturing individual stamps is one of the most beautiful ways of processing rubber. JustLaser offers you the perfect technology for manufacturing stamps through laser engraving!

Which types of ruber can be engraved using a laser engraver?

Due to the great flexibility of modern laser machines, a wide variety of types of rubber can be processed using laser processes:

- Natural rubber

- Laser rubber

- Foam rubber

- Silicone rubber

- Synthetic rubber, etc.

Engraving text plates for stamps with a laser

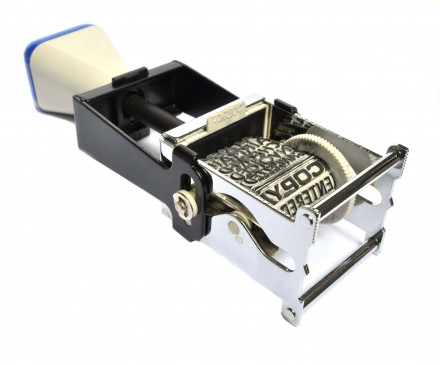

With efficient JustLaser Laser Engravers, you can process rubber stamp text plates quickly, efficiently, and in an environmentally-friendly way – entirely without using any poisonous chemicals. Detailed motifs, classy lettering and logos with recognition value are just some of the example applications for producing stamps through laser engraving. If a stamp text plate is produced, the design must be mirrored and inverted to make sure that the impression is legible. The laser software for our JustLaser Laser Engravers automatically chooses the appropriate settings for you, thus making stamp creation easier.

Laser engraving refer to a process in which a material is vaporised and removed using a laser. This produces a permanent engraving. As lasers are extremely flexible and precise tools, even fine and detailed designs can be produced easily. Furthermore, rubber can also be cut along predefined shapes using lasers. The result is a particularly fine cutting gap. This means that even unusual and complex contours are no problem for the laser technology from JustLaser.