Robust materials, high-performance coatings such as DLC and completely intact surfaces are a must in numerous industries and especially in medical technology. The legally required marking of clearly defined components as well as medical and surgical instruments is therefore usually carried out using lasers. DLC laser marking using laser machines from JustLaser offers numerous advantages.

What is DLC?

DLC stands for diamond-like carbon and refers to a high-performance coating made of a diamond-like carbon layer. DLC coatings thus possess some of the special qualities of diamond and combine a high micro-hardness and chemical resistance with a particularly low coefficient of friction.

The properties of DLC at a glance

DLC is characterised by a number of remarkable properties or advantages:

- high surface hardness

- low sliding friction

- long durability

- reduced maintenance

- ideal biocompatibility

- high corrosion and temperature resistance

- high chemical resistance etc.

Where is DLC used?

DLC is ideal for use in a wide variety of areas - especially wherever the properties of parts, tools and components, such as in the automotive industry, can be significantly improved by the particularly hard sliding layer that reduces friction and wear. In addition, the DLC coating is also used in medical technology and the food industry to improve biocompatibility and, due to its luxurious appearance, also in decorative processes.

The most important areas of application for DLC coatings are implants, orthopaedics, sliding rails and bearings, drills, piston cylinders, forming tools, automotive technology and mechanical engineering as well as blades, watches and weapons.

Marking of medical technology products

In medical technology, DLC laser marking of medical and surgical instruments as well as implants etc. by means of UDI (Unique Device Identification) or MDR (Medical Device Regulation) is required by law, because for the safety of patients and doctors, manufacturer's data must be traceable at all times and permanently. They contain production data, serial or batch numbers, product and manufacturer information as well as clear markings as protection against plagiarism. Almost all commercially available smartphones can decode the machine-readable codes (data matrix codes, rarely barcodes) in the field quickly and with a high degree of reading reliability.

Laser marking of DLC

Particularly in medical technology, important requirements are placed on the marking of high-performance coated components, which is why DLC laser marking is the leading process. This is because laser markings are durable, resistant to bodily fluids, cleaning agents and disinfectants as well as many acids and alkalis, and are convincing with optimal biocompatibility.

Colour change as the preferred process

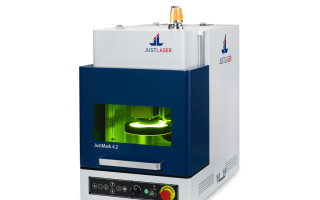

The efficient and precise JustMark laser marker from JustLaser is recommended for DLC laser marking. In most cases, medical technology products are marked by means of colour change. In this process, the laser marker achieves high contrast on the material surface, leaving it completely intact. There is no (significant) material removal. Thus, this marking is not only corrosion-free, but also sterile, as it does not form a surface of attack for any germs.

The marking with the JustMark laser marker is (almost) impalpable and convinces with very high contrast, best resolution and edge sharpness. For example, a QR code with 25 alphanumeric characters and an edge length of just 5.5 mm can be easily read with the camera of a modern smartphone. This does not even require a scanner app. The entire marking process with the JustMark laser marker takes only 5.5 seconds with quality-optimised marking.