You can cut organic materials like wood, plastic and textiles with both the JustLaser Large Laser Cutter and the JustLaser Laser Engraver. The JustLaser Large Laser Cutter can also cut metals with a thickness of up to 4 mm. The JustCut range of products with an output of 1kW - 3kW from a fibre laser can cut metals with a thickness of up to 10mm.

- Laser Machines

-

Benefits of laser technology

- Laser Cutting instead of CNC Milling

- All the benefits of buying your own laser machine

- Laser engraving instead of sandblasting

- Laser Cutting VS Cutting Plotter

- Laser Cutting VS Water Jet Cutting

- Laser engraving machine instead of an engraving machine

- Laser marking instead of needle embossing

- Laser marking instead of etching

- Inkjet vs laser processes

- Engraving metal with a laser engraving machine

-

Laser Applications

- About us

- Contact

- Blog

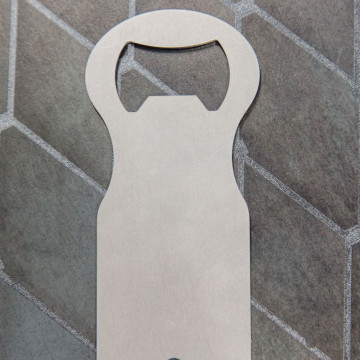

- Laser Cutting

- Acrylic

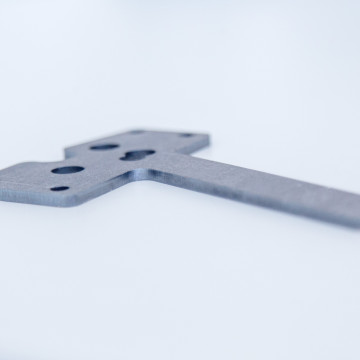

- Aluminium

- Aramids and Kevlar

- Architectural Models

- Sheet Metal and Copper

- Corian

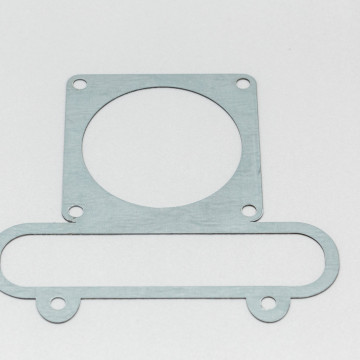

- Seals

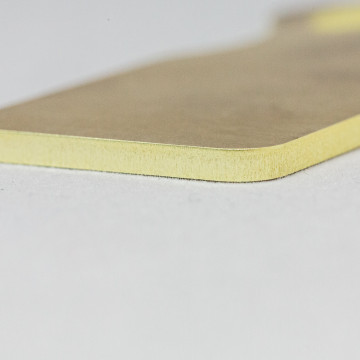

- Finishing

- Stainless Steel

- Fab labs and Universities

- Felt

- Front plates

- Wood

- Handicrafts

- Leather

- Metal

- Paper and Cardboard

- Polycarbonate

- POS Displays

- Product design and prototyping

- Foam

- Toys

- Styrofoam

- Film

- Textiles

- Packaging

- Business Cards

- Laser Cutting instead of CNC Milling

- All the benefits of buying your own laser machine

- Laser engraving instead of sandblasting

- Laser Cutting VS Cutting Plotter

- Laser Cutting VS Water Jet Cutting

- Laser engraving machine instead of an engraving machine

- Laser marking instead of needle embossing

- Laser marking instead of etching

- Inkjet vs laser processes

- Engraving metal with a laser engraving machine