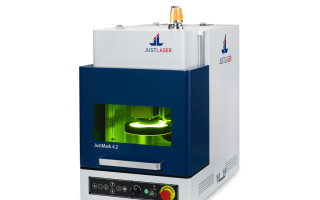

Für die Anforderungen der Laserbeschriftung elektronischer Teile und Halbleiter kommen zwei Lasersysteme in Frage.

Faserlaser erfreuen sich steigender Beliebtheit bei der industriellen Kennzeichnung, schließlich erzeugen sie permanente, präzise Markierungen mit hohem Kontrast und können sowohl blanke als auch beschichtete Metalle markieren. Darüber hinaus überzeugen die Faserlaser mit einfacher Bedienung, langen Betriebslaufzeiten und arbeiten kostengünstig und nahezu wartungsfrei.

Dank Lasermarkiermittel ermöglichen CO2-Laser die Direktmarkierung von Kunststoffen und Materialien jeglicher Art. Dieses wird vor dem Laserprozess auf das Material aufgetragen und beim Lasermarkieren in die Oberfläche eingebrannt. Dabei entsteht eine dauerhafte, schwarze Kennzeichnung.