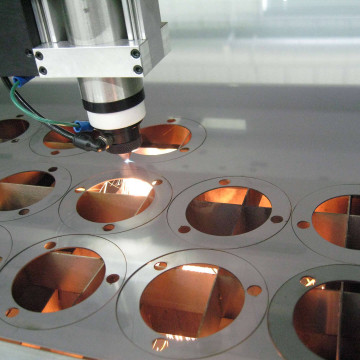

Laser cutting is a thermal cutting process in which the metal to be cut is removed from the cutting gap by a continuous or pulsed laser beam. The material is cut according to specified patterns which are traced by a precise laser beam. The efficient CO2 laser or fibre laser are usually used for this. At JustLaser, you’ll find the ideal laser cutter for cutting metals 6 mm or 5 mm thick and made from aluminium, sheet metal and copper or acrylic. In laser cutting, basic distinctions are made between three different methods, depending on the material thickness and the requirements of the workpiece:

LASER FLAME CUTTING

Laser flame cutting is carried out with the help of the cutting gas oxygen. This ensures exothermic oxidation processes, i.e. the energy released as heat by the combustion of metal supports the cutting process. This method is suitable for manufacturing parts quickly.

LASER FUSION CUTTING

In laser fusion cutting, inert gas is blown into the cutting joint and thus prevents or severely inhibits reactions with atmospheric oxygen. The cut edge and the surrounding metal is also cooled. It forms a low-oxide cut edge which is beneficial for all workpieces which should not be subjected to post-processing, or where no material change is desired.

SUBLIMATION CUTTING

Sublimation cutting is done without cutting gas and is used for thin metal sheets (up to approx. 3 mm thick). The laser causes the material to be vaporised, which produces a fine, often burr-free cutting gap.