The design and function of a rolling bearing are extremely simple: rolling bodies in between two thrust rings or bearing rings ensure the reduction of frictional resistance. They are often used for fixing shafts or axles and are used wherever something needs to turn smoothly. They are usually used in drive engineering – in turbines, ship’s propellers, motors, as well as in drills or medical devices – to guarantee that machines with rotary motion run smoothly and efficiently.

A ball bearing is a type rolling bearing in which the balls serve as rolling elements. They reduce frictional resistance, bear loads and position moving machine parts.

Why do ball bearings need to be labelled?

Partial labelling for the purposes of identification and traceability is now compulsory for safety reasons in a number of industries. Having your ball bearings marked with a laser has a number of benefits, especially if you need to guarantee the traceability of components. Laser marking is forgery-proof, permanent and is even resistant to mechanical and thermal stress. It is frequently used for the following functional inscriptions on ball bearings:

- Codes for tracing

- Company name or logo to protect against forgery

- Product information and functional inscriptions such as size, type or production date

- Serial numbers, batch numbers, production codes, etc.

Which materials can be labelled using a laser?

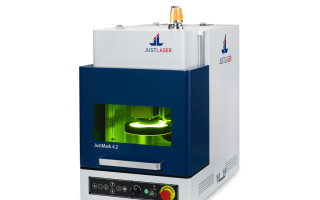

It doesn’t matter which material ball bearings needing to be marked are made from – the modern laser marker from JustLaser can produce permanent, precise and forgery-proof marks on almost any surface: