In the jewellery industry, laser engraving is used for customising and finishing a variety of pieces of jewellery and products. When hit by the laser beam, the material is heated to such an extent that its surface is vaporised. This creates a permanent and abrasion-resistant engraving. At lower temperatures, alloy components (in alloys) may become separate (diffusion), thus providing an aesthetically-pleasing inscription.

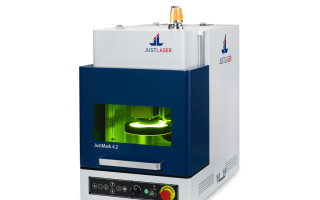

Our engraving software gives you the creative freedom you need to design your individual pieces of jewellery. Fonts and symbols are constantly being expanded, picture templates from customers and even templates made by hand can be reproduced exactly. Whether it’s individual pieces or entire product ranges – with JustLaser laser machines, you’ll reliably achieve the best results.

Ring Engraving on the inside and seamless engraving all around the ring

The classical applications of laser engraving in the jewellery industry include inscribing exterior, interior and end surfaces and using a laser to seamlessly engrave all around the circumference of a ring. The high precision and flexible configurability of JustLaser laser machines make it possible to produce even the smallest and most delicate motifs like no other process. The finest line widths can be reproduced in top quality and in a way that is true to the original.

3D Laser Engraving

3D laser engraving in the jewellery industry facilitates the creation of complex, three-dimensional material surfaces (a 3D internal engraving in the material – e.g. acrylic) on a wide range of materials. The laser engravers from JustLaser guarantee maximum accuracy and repeatability at high production speeds.

Surface Structuring and frosting

The laser machines from JustLaser can also be used to selectively structure material surfaces, engraving small structural elements into a smooth surface. Another application is the frosting of polished surfaces, the amount of time and effort for which is significantly decreased by the use of a highly modern laser.

In addition, laser engraving in the jewellery industry is also used for inlay work, channel setting, hallmarking and engraving crystals.