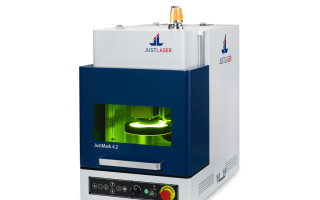

A laser engraving device for metal laser engraving from JustLaser is ideally suited for industrial laser marking, as it is frequently used in tool and machine construction, in the electronics sector as well as in the automotive industry and medical technology for functional labeling and coding, production information and product labeling as well as type plates. Especially in industries where the traceability of components is mandatory for safety reasons, you benefit from the durable, abrasion-resistant, high-contrast as well as heat- and acid-resistant laser engraving or marking by JustLaser.

In addition, JustLaser's laser machines can also be used for the creative design and personalization of advertising materials and gift items. This extremely time- and cost-efficient method is popular with sign makers, engravers or in the advertising industry for processing products such as information signs, jewelry, smartphones and notebooks, lighters, etc.

In addition, a laser engraver from JustLaser can also be used for color marking on stainless steel. This is a special type of annealing marking. Generally, in this form of marking, the heat of the laser triggers an oxidation process below the surface of the material, which leads to a color change. The surface remains completely unaffected. Depending on the temperature selected, different colors can be achieved during marking, which opens up new possibilities, especially in creative laser marking.