When it comes to medical technology, laser marking is considered standard for marking a wide variety of instruments. Depending on the requirements, laser marking medical technology can be used to record a variety of information: UDI (Unique Device Identification) and MDR (Medical Device Regulation) contain production data, serial or batch numbers, product and manufacturer information and unique labels to protect against forgery. As laser inscriptions are resistant to bodily fluids, cleaning agents, disinfectants and acids, they have become indispensable in the medical sector. The markings are also sterile and, thanks to the fact that they do not alter the surface, there is no area for germs to build up. Another advantage is the optimal biocompatibility: implants marked with a laser can remain in the human body without any problems for a long time without any materials coming away from the inscription.

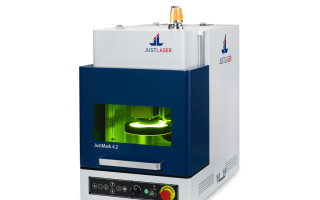

Depending on the material, you can use a JustLaser Laser Marker to mark the following products in a sterile and durable way: implants, medical and surgical instruments, plastic cannulas, orthopaedic implants, pacemakers, dental drills, titanium bone screws, technical ceramic, surgical tools, and many more. The robustness of the markings is even ensured with frequent use and frequent cleaning. Laser markings guarantee the important data can be read electronically for the long-term. This is the only way to ensure a product can be traced for its entire lifespan.