Seals are exposed to great stresses in industrial and private use. Their function is usually essential for quality assurance. Seals also play an important role with regard to environmental and safety awareness. After all, they are supposed to keep unwanted – and sometimes even harmful – materials out of end products and other areas. Not least because of this, an exact cut is enormously important for their functionality.

Seals made from rubber, cardboard or other sealing materials can be processed using a CO2 laser with such precision that high-quality results are guaranteed. When cutting seals / sealing material with a laser, you can work with your usual graphics program right from the start. Your staff do not need to be trained. See for yourself – you’ll be delighted by the precise – and, thanks to the thermal laser process, sealed – cutting edges and the ease of use!

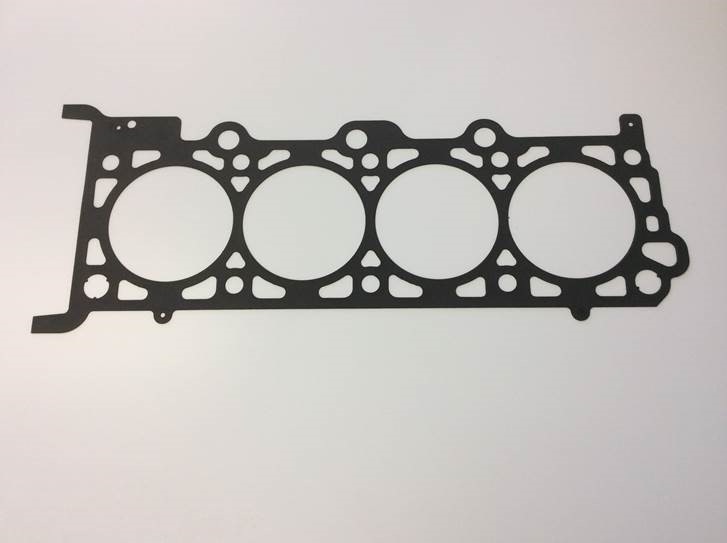

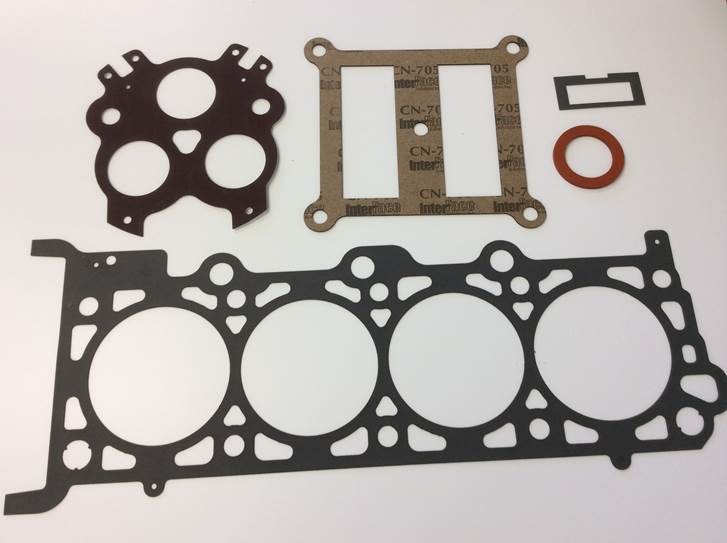

CUTTING RUBBER SEALS WITH A LASER

Seals made from rubber have applications in both industry and private use. A smooth cut with exact edges is produced when cutting rubber with a CO2 laser. This is hugely beneficial when cutting seals / sealing material with a laser – top quality is demanded here, after all.

A number of types of rubber can also be engraved using a laser. Logos, inscriptions and manufacturing parameters are produced on the rubber with maximum precision. Both low quantities and serial productions can be produced quickly and easily with a JustLaser Laser Engraver.

CUTTING CARDBOARD SEALS WITH A LASER

Cardboard is a thick paper product that is also used in the production of special seals. The laser process is extremely advantageous as seals must be cut particularly precisely. A 9.3 µm or 10.6 µm CO2 laser is usually used when cutting cardboard with a laser – both variants guarantee high-quality results with clean cutting edges and low discolouration. Individual pieces can also be produced quickly and easily in this way.

Of course, in addition to cutting seals / sealing material with a laser, it is also possible to mark cardboard with a laser: This produces a permanent surface marking without any depth, and which becomes lighter or darker depending on the material. Additional depth and contrast can be produced when engraving with a laser.