There are a number of options when it comes to cutting advertising displays with a laser. Lasers are flexible with regard to shape, contours and material, and guarantee high-quality solutions for every challenge. The following materials are often cut with lasers in advertising:

APPLICATIONS OF LASER TECHNOLOGY IN ADVERTISING

A JustLaser Laser Cutter is versatile. The process of cutting advertising displays with a laser impresses thanks to its flexibility and speed. Regardless of the material or application – precise results are guaranteed. A range of thicknesses, shapes, letters, templates and patterns can be produced in a cost-effective way. As an “all-rounder”, the laser can process soft materials just as easily as hard or flexible ones. It’s not for nothing that you can find laser-cut signs everywhere nowadays – regardless of whether they’re for schools, museums, bank or company buildings or businesses premises. A number of products in the advertising industry are cut using lasers, such as:

CUTTING ACRYLIC GLASS WITH A LASER IN ADVERTISING

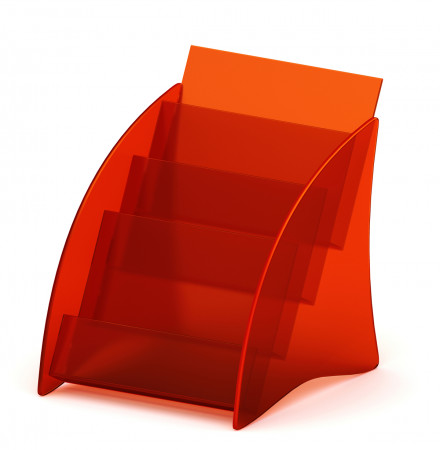

Stand-up displays and illuminated advertising are particularly well-suited to being processed with a laser. Both cast acrylic and extruded acrylic can be cut using a laser. Cast acrylic impresses with a wide selection of colours and thicknesses. Laser engraving produces an aesthetically pleasing matte finish. Crystal-clear edges and perfect right angles are just a couple of the benefits that make laser cutting the technology of choice.

Extruded acrylic is available on thinner plates or film and in fewer colours. It impresses with its cost-effective price. It can be cut quickly and easily using a laser, but, unlike with cast acrylic, no elegant matte finish is produced. The result from laser cutting is just as precise with a sharp burr at the laser’s exit point.

A glossy cut edge is often desired on acrylic when cutting displays with a laser in advertising. An aesthetically impressive, glossy, flame-polished cut edge can be produced depending on the type of acrylic, the system and the requirements.