Special materials in furniture construction

From leather to stone - setting exclusive accents with laser technology

Furniture construction has constantly evolved over time and integrated new materials and technologies. Nowadays, special materials play a decisive role in creating unique and exclusive pieces of furniture.

Individuality is more important than ever in high-quality furniture construction. Standardized series solutions are often not enough to convince discerning customers. Instead, exclusive furniture materials such as leather, technical textiles, acrylic or modern materials such as Corian® are gaining in importance. These special materials not only enable unique designs, but also open up completely new design possibilities thanks to modern production technologies such as laser engraving and laser cutting.

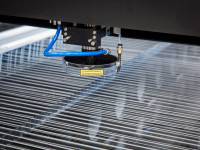

The targeted use of laser technology - for example with the JustLarge CO₂ laser machine from JustLaser - ensures maximum precision, repeat accuracy and a surface quality that can hardly be achieved with conventional processes.

Leather in furniture construction: finishing with style - and with the laser

Leather is one of the noblest and most traditional materials in furniture making. With its natural feel, characteristic ageing and durability, it is a symbol of value.

Types of leather

There are various types of leather used in furniture making. The best known include

- Smooth leather: This leather is particularly easy to care for and hard-wearing. It is often used for sofas and armchairs and gives these pieces of furniture an elegant look.

- Suede: Suede is softer and more supple than smooth leather. It is mostly used for chairs and small pieces of furniture and creates a warm and cozy atmosphere.

- Nubuck leather: This leather is particularly velvety and pleasantly soft to the touch. However, it is more sensitive than smooth leather and therefore requires careful care.

Advantages of leather in furniture making

Leather offers numerous advantages in furniture construction:

- Durability: leather is extremely hard-wearing and can last for many years if cared for properly.

- Ease of care: Smooth leather is easy to clean and resistant to stains.

- Aesthetics: Leather gives furniture an elegant and luxurious look.

- Comfort: Leather adapts to the body temperature and offers a pleasant sitting experience.

Laser engraving on leather: precise, durable, individual

With the JustLarge CO₂ laser, a wide variety of leather types - from genuine leather to synthetic alternatives - can be engraved or cut with high precision.

This opens up new possibilities for individualization:

- Logo engravings for brand furniture or customer projects

- Decorative patterns, ornaments or surface structures

- Made-to-measure cuts for leather inlays or coverings

- Personalization for individual items, hotel furnishings or design collections

The engraving is durable, abrasion-resistant and colorfast - without damaging the material structure. In addition, there is no burr or distortion, as can occur with mechanical processes.

Textiles and technical fabrics: flexibility meets function

Textile materials are also increasingly being used in modern furniture construction - for example as acoustic panels, wall coverings, privacy screens or as design elements on fronts and upholstery.

Laser cutting of textiles: accurate and fiber-free

Laser technology offers a clear advantage over scissors or punches: sharp cuts without fraying.

The laser seals the edges by applying heat locally - ideal for:

- Technical textiles, such as polyester, glass fiber fabrics or outdoor fabrics

- Felt and wool fabrics for acoustically effective wall modules

- Thin lengths of fabric for covering furniture or panels

- Special fabrics with a coating that are difficult to cut mechanically

With the JustLarge, even multi-layer fabrics can be processed simultaneously - ideal for series or modular systems.

Acrylic in furniture construction: modern, clear, translucent - perfect for the laser

Acrylic glass has become an integral part of modern furnishing concepts. Whether as a light cover, partition wall, lettering or decorative element - the material impresses with its transparency and versatility.

Laser cutting of acrylic: smooth edges, no post-processing

When cutting acrylic, the JustLarge offers a particularly smooth, almost polished cut edge that is ready for immediate installation.

This saves time and ensures a flawless finish - especially with:

- Light fixtures with backlit acrylic

- Engraved logos or ornaments for branded furniture

- Transparent shelves, fronts or displays

Engraving is also possible - for example for elegant light-scattering effects on translucent acrylic panels.

Corian® & composite materials: lasering for modern surfaces

Corian® and similar solid surface materials (e.g. HI-MACS®, Krion®) are increasingly being used in high-end interior design - whether as worktops, washbasins, wall cladding or furniture surfaces.

Laser engraving on Corian: subtle effect with a wow factor

Thanks to its homogeneous structure, Corian is ideal for fine engravings - such as logos, design elements or tactile markings. Particularly effective accents are created in combination with LED backlighting.

While laser cutting is only possible to a limited extent with thicker panels, the great advantage of the laser here is the surface finishing without tool contact - especially for large surfaces or series production.

Stone - robustness and exclusivity

Stone is another exclusive material used in furniture construction. It gives furniture a robust yet elegant appearance. Stone furniture is not only visually appealing, but also extremely durable and easy to care for.

Types of stone

There are different types of stone used in furniture construction:

- Marble: Marble is a noble and luxurious stone that is often used for tables and worktops. It gives furniture an elegant and timeless look.

- Granite: Granite is particularly robust and hard-wearing. It is often used for kitchen worktops and washbasins.

- Slate: Slate is a versatile stone that can be used both indoors and outdoors. It gives furniture a modern and rustic touch.

Advantages of stone in furniture construction

Stone offers numerous advantages in furniture construction:

- Durability: stone is extremely robust and can last for many years.

- Easy to clean: Stone is easy to clean and resistant to stains and scratches.

- Appearance: Stone gives furniture an elegant and luxurious look.

- Versatility: Stone can be used in various designs and shapes and adapts to different furnishing styles.

Design diversity meets efficiency: laser technology as a driver for innovation

Processing special materials using conventional methods is often time-consuming, error-prone or expensive.

Laser technology sets new standards here - especially in furniture construction with exclusive materials:

- Finest engravings on leather, textile, acrylic and composite materials

- Precisely shaped cuts without tool wear

- High reproducibility for series products with manufacturing quality

- Non-contact processing without distortion or damage to the surface

The JustLarge CO₂ laser system provides joineries, interior design offices and furniture manufacturers with a solution that meets the highest demands in both one-off production and series production - both technically and in terms of design.

Targeted use of special materials - with the precision of the laser

Leather, textiles, acrylic, Corian or stone - the future of furniture design lies in the skillful combination of high-quality materials with modern production technologies. The use of laser technology opens up completely new perspectives in furniture construction with exclusive materials: faster, cleaner, more flexible.

FAQ: Laser processing of special materials in furniture construction

Which materials can be processed with the JustLarge CO₂ laser from JustLaser?

The JustLarge is ideal for organic materials such as leather, textiles, acrylic, wood, MDF, veneers and many composite materials such as Corian® or HI-MACS®. Thin technical plastics can also be precisely cut and engraved.

Is laser engraving on leather permanent?

Yes - engraving on genuine leather or artificial leather is durable, abrasion-resistant and UV-resistant. It does not change the material structure, but creates a subtle, high-contrast surface with a high level of detail.

Do textiles fray during laser cutting?

No - when textiles are laser cut, the cut edges are thermally sealed. This creates a clean, fiber-free edge without mechanical stress. Ideal for fabrics with a tendency to fray, such as polyester or blended fabrics.

How does laser cutting acrylic differ from milling?

Laser cutting produces smooth, shiny cut edges - without the need for polishing. In contrast to milling, there is no chip formation, no tool wear and a significantly higher level of detail, especially with intricate contours.

Can Corian® be cut with a laser?

Thin Corian layers or veneers can be cut, while thicker sheets can be engraved. The laser creates decorative patterns, textures or logos on the surface - ideal for design accents or backlit elements.

Can the JustLarge also be used to cut metal?

Yes, thanks to its unique design and the super-pulsed laser tube, it is possible to cut thin sheets on the JustLarge using a metal cutting option.

Is laser technology economical for small series or individual pieces of furniture?

Yes - thanks to the digital workflow, the elimination of tool changes and the high precision, it is also worth using it for short runs, one-offs or customized solutions.