The smart joinery

Laser as a digital building block for efficiency

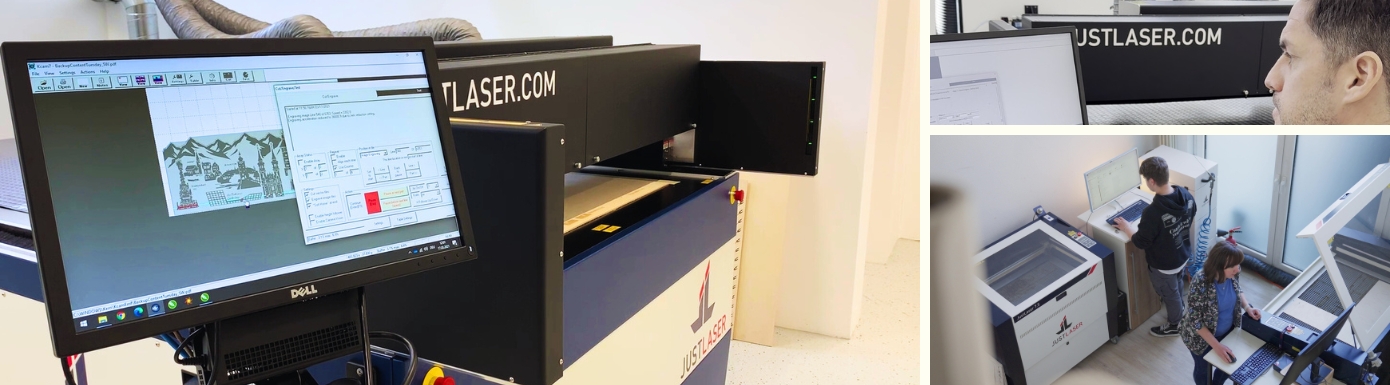

The digitalization of the skilled trades is no longer a promise for the future - it is reality. In furniture construction and interior design in particular, it is clear that anyone who wants to work economically, flexibly and with sophisticated design in the future will not be able to avoid digitally networked processes. The "smart joinery" is the new guiding principle - and the laser is a key tool in this transformation.

As a precise, digitally controllable and material-flexible technology, the CNC laser fits seamlessly into the digital workshop. In combination with CAD/CAM systems and networked workflows, it is transformed from a classic tool into a productive control center - efficient, versatile and economical.

Looking ahead to LIGNA 2025, the world's leading trade fair for tools, machines and technologies for woodworking and wood processing, it is clear that the future of the carpentry trade is networked. And JustLaser is right in the middle of it.

From design to reality: how the laser complements digital processes

In modern joinery, the production process no longer begins at the workbench - but on the screen. Furniture designs are created in CAD software, planned digitally and translated directly into production data. This is exactly where the laser comes in.

Digitalization meets craftsmanship: the new workflow

- Planning in the CAD system

Whether individual pieces of furniture or a series - shapes, contours and connections are designed directly on the computer.

- Transfer to CAM

The data is processed automatically - for example, translated into nested cutting plans or engraving patterns.

- Data transfer to the laser

The CNC laser receives the information and converts it 1:1. No reprogramming, no readjustment.

- Feedback to the workshop control system

Production times, material consumption and production status can be recorded and processed digitally.

This seamless process not only saves time, but also makes the workshop more transparent, controllable and future-proof.

The benefits of laser integration for joineries

The integration of laser machines such as the JustLarge CO₂ laser into digitized workshop structures brings several advantages - especially for small and medium-sized companies that need to react agilely to customer requests:

1. maximum flexibility with materials

Whether wood, MDF, acrylic, veneers, textiles, leather, technical plastics or even thin sheet metal - a single laser system can process a wide variety of materials. Perfect for manufactories with a high degree of individualization.

2. design freedom without changing tools

Creative shapes, free contours, intricate engravings: the laser works contactlessly, wear-free and without set-up times. This facilitates special solutions, batch size 1 projects and prototyping.

3. increased efficiency in production

The direct connection to CAD/CAM software shortens planning and production steps. Sources of error during data transfer are eliminated - exactly what was planned is produced.

4. precision at industry level

The CNC-controlled laser cuts and engraves with tenths of a millimeter precision. Ideal for precisely fitting components, miters, plug connections or detailed elements.

5. calculable costs through digital control

Thanks to feedback with ERP or MES systems, quantities, processing times and material usage can be precisely evaluated - a solid basis for economic decisions.

The JustLarge from JustLaser: Optimized for the smart workshop

In response to the requirements of digital joinery, JustLaser has developed the JustLarge CO₂ laser - a powerful solution that integrates perfectly into modern workshop processes.

Features that make the JustLarge special:

- Large working area for cutting entire panels or extensive nestings

- Software compatibility with common CAD/CAM solutions

- High cutting quality for organic materials such as wood, MDF, leather or acrylic

- Open interfaces for integration into workshop networks or automation solutions

- Intuitive operation - ideal for smaller teams or changing personnel

This makes the JustLarge a versatile "all-rounder" for the digital workshop - from classic furniture construction to special applications in store fitting, object design or interior design.

Why the topic is particularly topical at LIGNA 2025

LIGNA 20 25 has the guiding theme "Transformation of woodworking - digital, automated, sustainable". JustLaser will be demonstrating how digital technology and traditional craftsmanship are not mutually exclusive, but complement each other perfectly.

For joineries and carpentry businesses, this is an opportunity to get to grips with new technologies at an early stage - and to gradually transform their own workshop into a digital production environment.

Laser technology is not seen as a substitute for manual skills, but as a modern extension of them - fast, precise and versatile.

Conclusion: The CNC laser as the key to smart joinery

Digitalization is changing furniture construction - both in the workshop and on the market. Any joinery that wants to remain competitive in the long term must take advantage of the opportunities offered by new technologies.

CNC lasers such as the JustLarge from JustLaser are more than just machines - they are universal digital tools for creative freedom, efficient processes and the highest quality.

They make it possible to combine traditional craftsmanship with the requirements of the future: modular, flexible, software-based - and yet authentic.

FAQ: Laser integration in the smart joinery

What software is required for laser control?

The JustLarge is compatible with many common CAD programs. The transfer takes place via file formats such as DXF, SVG or AI. The JustLaser software supplied enables simple assignment of cutting and engraving paths.

Can a laser be integrated into existing workshop processes?

Yes. The laser can be integrated into existing digital workflows, ERP systems or machine parks via network connections, open interfaces and standardized file formats - manually or automatically.

Which materials is the JustLarge particularly suitable for?

The JustLarge processes wood, MDF, veneers, acrylic, leather, textiles and many plastics precisely and without contact. Even multi-layered materials can be cut or engraved in a single operation.

Is the laser also economical for small series or individual items?

This is where the laser really comes into its own: No tool changes, no set-up times, quick changeovers - perfect for individual customer requests or prototype construction.

How does the joinery benefit from digitalization with lasers?

Laser integration creates a continuous, digitally controlled process: from the design to the finished component. This saves time, reduces errors and enables economical, future-proof production.