Laser cutting wood: How to avoid burn marks on your next project

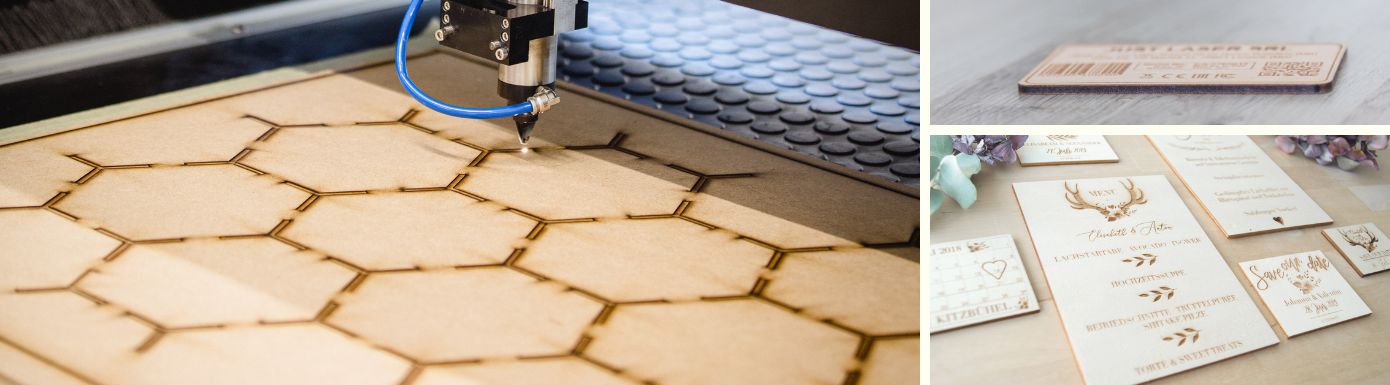

Tips for a more beautiful wood laser cut

When laser cutting wood, creativity and precision are required, but one of the biggest challenges is unwanted burn marks. These can significantly impair the end result and give the otherwise flawless project an unattractive appearance.

We show you how to avoid these burn marks and make your next laser project a success. From preparing the wood and selecting the right settings to monitoring the work process - our tips will help you minimize the risk of burn marks and achieve optimum results.

Why is it important to avoid burn marks when lasering wood?

Burn marks are caused by the intense heat of the laser beam, which not only cuts or engraves the wood, but can also burn it. These marks are particularly visible on the edges and in engraved areas where the laser remains in one place for longer.

Avoiding burn marks is extremely important when lasering wood. This is because they not only impair the visual appearance of the finished product, but can also lead to a hazard. The resulting scorch marks can spread and, in the worst case, cause a fire.

It is therefore important to ensure careful preparation and correct handling of the laser device when lasering wood. Selecting the right settings and choosing the right type of wood are also crucial for an optimum result without burn marks.

Step 1: Preparing the wood before lasering

Before you start lasering wood, it is important to prepare the wood properly. A smooth and even surface of the wood is necessary to achieve an optimal result when lasering and to avoid burn marks. Therefore, sand the wood thoroughly and clean it of any dust or residue.

If the wood has already been treated, carefully remove any varnish or paint. It is best to use a suitable paint stripper or sandpaper for this. Make sure that the wood is completely dry before you start lasering. A damp surface can result in the laser beams not attenuating correctly on the material, which can lead to unwanted burn marks.

Once your wood is clean and dry, you're ready for the next step: choosing the right settings for your laser machine!

Step 2: Selecting the correct settings for the laser device

Once you've prepared your wood, it's time to choose the right settings for your laser machine. This step is often overlooked or considered unimportant, but it can have a huge impact on how the final product looks. There are several factors to consider when choosing the settings, such as the type of wood, thickness and hardness.

Choosing the right laser parameters is crucial to minimize burn marks. The key factors include:

- Power and speed: High laser power at low speed increases the likelihood of burn marks. Experiment with these settings to find the ideal balance for your specific wood material.

- Pulse frequency: With some lasers, you can adjust the pulse frequency to control the intensity of the laser beam and thus reduce burn marks.

If you are not sure what settings are required for your particular project, you should always do a test engraving or test cut and see if any adjustments need to be made. A good rule of thumb is also to start with low power and speed settings and gradually increase them.

Step 3: Safe handling of the laser device while working with wood

Now that the wood has been prepared and the settings for the laser device have been selected, it is important to ensure safe handling of the device. Ensure that the device is positioned correctly and that it is stable on a flat surface. Avoid unnecessary movements or vibrations during operation. You should also ensure that the work area is clean and tidy. Remove all combustible materials, including those inside the laser, from under the processing table.

When you start lasering, start with a low power setting and speed. Check the progress of your work regularly and adjust the settings if necessary. Remember that sparks can occur at higher power settings. Prevent this by regularly cleaning the lens and using an air compressor to reduce smoke and burns.

Overall: Be careful when handling the laser device! Always monitor the work process in order to recognize possible dangers in good time.

Tips for minimizing scorch marks on different types of wood

When laser engraving wood, it is important to minimize burn marks in order to achieve a high-quality result. However, every type of wood behaves differently and requires different procedures. For hardwoods such as oak or mahogany, the power of the laser device should be reduced to avoid overheating and the associated burns. Another option for reducing smoke development and burns is to use an air compressor.

Preventing sparks from forming can also help to minimize the risk of fire when lasering wood species such as pine or spruce. However, it is important to keep an eye on the work process at all times and recognize potential hazards in good time.

The importance of speed and power settings when lasering wood

One of the most important settings when lasering wood is the speed and power. It is crucial that these are set correctly to avoid burn marks. If the speed is too high or the power too high, the wood can burn and leave unsightly marks. However, if they are too low, the wood will not be cut cleanly and cracks may appear.

It is therefore important that you find out about the recommended settings for your laser device before lasering and adjust them accordingly. In the case of JustLaser laser engravers and laser cutters, there is already a large number of prepared cutting and engraving parameters for numerous types of wood and material thicknesses from our cooperation partners in terms of application material.

If you are working with a new laser device or with a type of wood that you have never processed before, you should first carry out test runs and try out different settings. In this way, you can find out which settings are best suited to your specific application.

When choosing the right speed and power settings, other factors must also be taken into account, such as the thickness of the wood and whether it is hard or soft.

The use of an air compressor to reduce smoke development and burns

When lasering wood, it is important to avoid burn marks in order to achieve a high-quality result. One way to reduce smoke development and burns is to use an air compressor while working with the laser device. The targeted air supply reduces the heat development in the material and therefore also minimizes the risk of burns.

The use of an air compressor achieves significantly clearer, more precise and therefore more attractive results in terms of engraving and cutting.

In combination with the correct settings for the laser device and safe handling, the use of an air compressor can help to ensure that lasering wood can be carried out effectively and safely.

Cleaning after lasering

If burn marks occur despite all precautions, these can often be removed with a little reworking:

- Fine sanding: A fine sanding process can remove superficial burn marks.

- Cleaning agents: Special wood cleaners can help to clean the surface of deep-seated marks.

Monitoring and control of the work process in order to identify potential hazards in good time

One of the most important aspects of lasering wood is monitoring and controlling the work process in order to identify potential hazards in good time. This is not just about avoiding burn marks, but also about the safety of the user. A watchful eye should therefore always be kept on the laser and the wood during work.

It is also advisable to take regular breaks to check the material and make adjustments if necessary. Good preparation and selecting the correct settings for the laser device are also essential to minimize risks.

Conclusion

In conclusion, it can be said that avoiding burn marks is very important when lasering wood. Many problems can be avoided by carefully preparing the wood and selecting the right settings for the laser device.

Safe handling of the appliance while working with wood and following tips to minimize burn marks on different types of wood are also important factors. The importance of speed and power settings as well as the use of an air compressor to reduce smoke and burns should not be underestimated either. It is also important to constantly monitor and control the work process in order to recognize potential dangers in good time.

Overall, the following applies: With a conscientious approach, burn marks can be effectively minimized when lasering wood - for a successful result without unpleasant surprises!