The key differences between glass and RF laser sources

Why a comparison between glass and RF laser sources is important

In the world of laser technology, choosing the right laser source is crucial for the efficiency and quality of your applications. Two of the most common types are the glass source and the RF source. Here we look at the differences between these two laser sources and why an investment in an RF source often proves worthwhile.

Why a comparison between glass and RF laser sources is important

A comparison between glass and RF laser sources is of great importance when it comes to making the best choice for your productivity. Both laser sources have their advantages and disadvantages, which can vary depending on the application. It is therefore important to carefully consider which laser source is best suited to specific requirements.

When purchasing a laser machine, it is not only the purchase cost that is important, but also the quality and type of laser source. Premium laser systems offer better application results, higher safety standards, longer durability and user-friendliness.

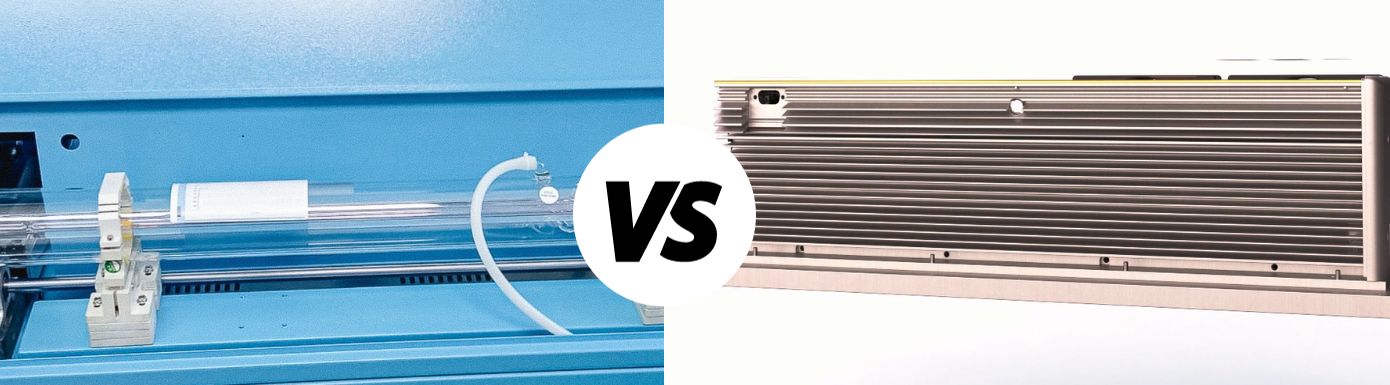

Definition of glass and RF laser sources

To understand the differences between glass and RF laser sources, it is important to first understand the definitions of both terms. A glass laser source uses solid-state laser technology in which a crystal such as ruby or yttrium aluminum garnet serves as an amplifier for the laser light. In contrast, an RF laser source uses radio frequency energy to generate laser beams.

Both technologies have advantages and disadvantages in terms of productivity and quality of work results.

Advantages of the glass laser source

The use of water-cooled glass laser tubes in laser technology offers an attractive price-performance ratio. These sources are not only cheaper to manufacture, but also to operate, as they use direct current to generate the laser beam. Especially in applications that require high power, glass laser sources can be superior from a cost perspective.

Technical challenges during implementation:

However, the construction of DC glass laser sources poses a number of technical challenges. One major difficulty is the integration of electrodes into the glass resonator, as glass and metal have different thermal expansion properties. This difference can lead to stresses and poses a risk to the integrity of the laser source, particularly in the event of temperature fluctuations. In addition, the penetration of ambient air into the resonator can impair the performance.

Another disadvantage of glass laser tubes is their limited pulse frequency due to the excitation process using direct current. This leads to longer excitation times and limits the speed at which precise engravings can be carried out.

Risks of water cooling

As glass is a poor conductor of heat, DC laser sources require water cooling to dissipate the heat generated. Although this cooling method is quiet, it increases the space required and the complexity of the system. A mismatch between the power of the laser and the cooling system can lead to serious damage to the glass tube.

Safety concerns and service life

An important aspect is the safety risk associated with DC laser sources, especially as they are operated at high voltages. Devices that do not comply with European safety standards pose additional risks. Furthermore, the lifetime of glass laser sources is limited compared to RF sources, which may require regular replacements.

Advantages of the RF laser source for productivity

RF sources, such as those used in laser machines from JustLaser, represent an advanced technology in laser technology. These sources consist of a robust metal housing that hermetically seals the contained gas mixture (N2, CO2, He). In contrast to glass laser sources, RF sources do not require a feedthrough, as an antenna radiates directly into the resonator and the gas is excited with high-frequency alternating current. This results in a lower voltage and increased safety.

One of the biggest advantages of an RF source is the high pulse frequency. With fast rise and fall times of up to 60µs at an average power of 400W, RF sources enable the generation of extremely fast and repeatable laser beams. This enables high precision engraving, even with small lettering and intricate lines.

RF sources are characterized by their compact design. All components, including the optical components, the electronics for gas excitation and the air cooling, are housed in a solid metal housing. This not only saves space, but also costs in terms of system integration.

Disadvantages and economic efficiency

The main disadvantage of RF sources is their higher acquisition costs. The antenna driver, which is necessary for the fast and frequent switching of the high electrical power, makes the system more expensive. The frequency of the radiated waves must be precisely tuned in order to achieve the highest possible efficiency.

Longer service life

RF sources are known for their long service life, provided that the resonator is well sealed after filling and the electronics are effectively cooled. On average, these sources deliver consistently high performance for five to six years and can be refilled with CO2 if necessary, extending their useful life to up to ten years.

While glass laser sources can be attractive due to their favorable price/performance ratio, metal RF sources offer better performance, especially for demanding engraving tasks. Their higher initial cost is offset by faster engraving speeds, higher quality, longer service life and improved work safety.